Tip

See our video guides for quick tutorials that walk you through Sigmacalx basic functionalities and concepts. This is the easiest and quickest way to get going with Sigmacalx forms.

There are three different equations to calculate the equivalent stress on an object with a cylindrical shape:

Formulas to calculate those stresses are taken from API 5C3 standard (A.1.3), and are valid for "thick-walled" pressure vessels with their wall thickness greater than one-tenth of the overall diameter.

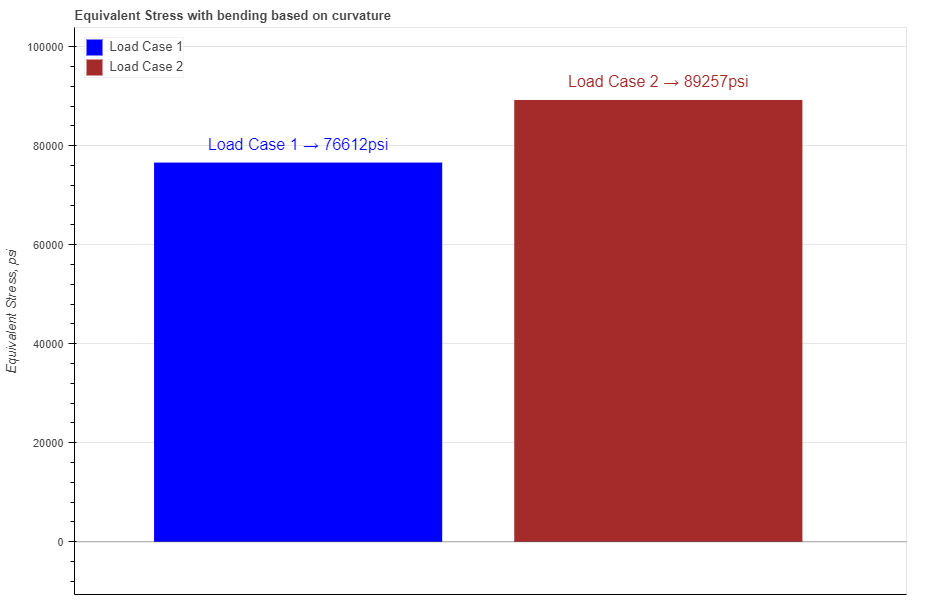

When you navigate to the "ES Equation - Bending, curvature" page, you will come across two buttons: and These buttons allow you to include up to 5 distinct pipe specifications and up to 20 different load cases. By incorporating multiple pipes and load cases into the plot, you can conveniently compare them to one another, enabling the observation of boundaries and safe regions. An example illustrating this can be seen in Figure 19.

Figure 19: Two equivalent stresses are presented as graphical bars based on the magnitudes entered in load cases.

Hovering your cursor over any of these bars reveals headers specific to each load case. The description labeled "Location" at the lowest point indicates whether the maximum stress occurs on the outer or inner diameter of the pipe.

In the pipe section you have 2 required parameters: Outside Diameter (OD) and Inside Diameter (ID)

There are 2 more optional parameters you may input on the tubing section: minimum Wall Thickness (mWT) and Corrosion Allowance (CA). Units for mWT is % and it is based on the specified manufacturing tolerance. Common number which is used for tubing and casing in the oil industry is 87,5%. Units for CA are either in or mm, depending which system you choose by pressing buttons Corrosion allowance is a measurement to the thickness of the wall. It is a metal loss throughout the lifespan of certain material in a certain conditions.

When you fill in all parameters for the pipe, press button. It is also a good practice to give a specific name for the pipe, for example: Tubing 7"-46#. This name will be shown on the generated report and on the selection menu in the load section.

Now you can specify the loading parameters for the pipe if you press button. Here you have an option to enter internal pressure (IP), external pressure (EP), axial force (Force), degree of the bend (Degree), arc length of the bend (LEN), Young's modulus (YM), torque around the longitudinal axis (Torque) and select the pipe you want to apply the loads for. If any of the magnitudes should not be specified then type 0.

Force can assume positive or negative values depending on whether it signifies tension or compression.

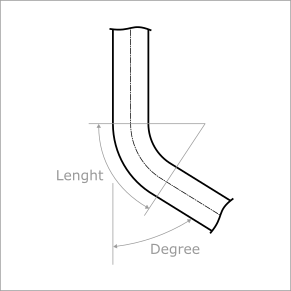

Below is an example of the loading parameters Degree and LEN.

Figure 20: Description of variables.

After you enter the required data for your analysis you can generate the report by pressing button. There you can fill the Project Name, Document Number, Created by and your Company Logo. You can also leave those fields blank and our company logo will be set on the report. To download the report you need to press button again. At the bottom of the export pop-up window you will find two html links. The first link is to download the report in PDF format and the other link is to download HTML plot, that might be useful to observe if you have high density data.

Below you may watch a short video tutorial of how to use the forms of this particular calculation.

Video: 10 ES Equation - Bending, curvature manual

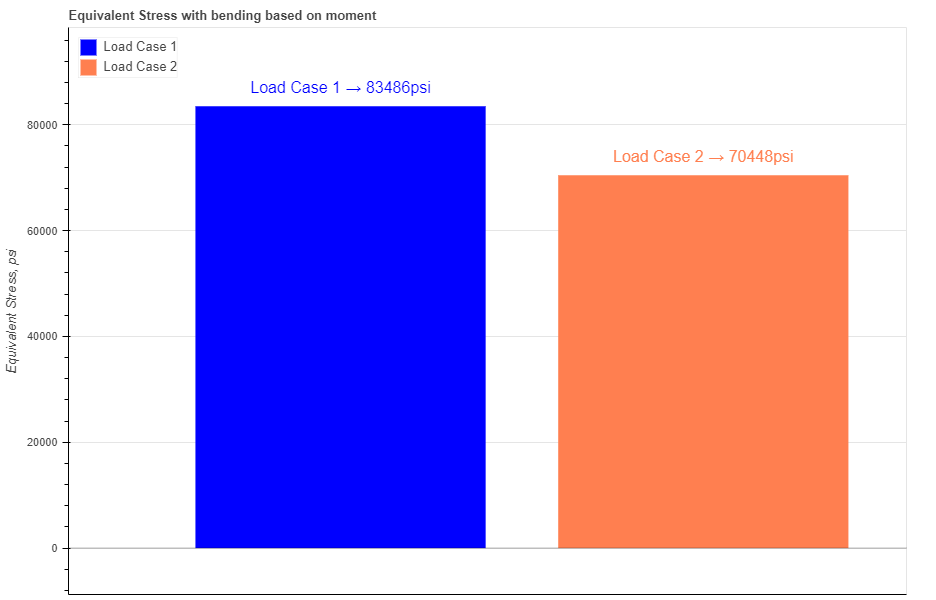

When you navigate to the "ES Equation - Bending, moment" page, you will come across two buttons: and These buttons allow you to include up to 5 distinct pipe specifications and up to 20 different load cases. By incorporating multiple pipes and load cases into the plot, you can conveniently compare them to one another, enabling the observation of boundaries and safe regions. An example illustrating this can be seen in Figure 21.

Figure 21: Two equivalent stresses are presented as graphical bars based on the magnitudes entered in load cases.

Hovering your cursor over any of these bars reveals headers specific to each load case. The description labeled "Location" at the lowest point indicates whether the maximum stress occurs on the outer or inner diameter of the pipe.

In the pipe section you have 2 required parameters: Outside Diameter (OD) and Inside Diameter (ID)

There are 2 more optional parameters you may input on the tubing section: minimum Wall Thickness (mWT) and Corrosion Allowance (CA). Units for mWT is % and it is based on the specified manufacturing tolerance. Common number which is used for tubing and casing in the oil industry is 87,5%. Units for CA are either in or mm, depending which system you choose by pressing buttons Corrosion allowance is a measurement to the thickness of the wall. It is a metal loss throughout the lifespan of certain material in a certain conditions.

When you fill in all parameters for the pipe, press button. It is also a good practice to give a specific name for the pipe, for example: Tubing 7"-46#. This name will be shown on the generated report and on the selection menu in the load section.

Now you can specify the loading parameters for the pipe if you press button. Here you have an option to enter internal pressure (IP), external pressure (EP), axial force (Force), bending moment (Moment), torque around the longitudinal axis (Torque) and select the pipe you want to apply the loads for. If any of the magnitudes should not be specified then type 0.

Force can assume positive or negative values depending on whether it signifies tension or compression.

After you enter the required data for your analysis you can generate the report by pressing button. There you can fill the Project Name, Document Number, Created by and your Company Logo. You can also leave those fields blank and our company logo will be set on the report. To download the report you need to press button again. At the bottom of the export pop-up window you will find two html links. The first link is to download the report in PDF format and the other link is to download HTML plot, that might be useful to observe if you have high density data.

Below you may watch a short video tutorial of how to use the forms of this particular calculation.

Video: 11 ES Equation - Bending, moment manual

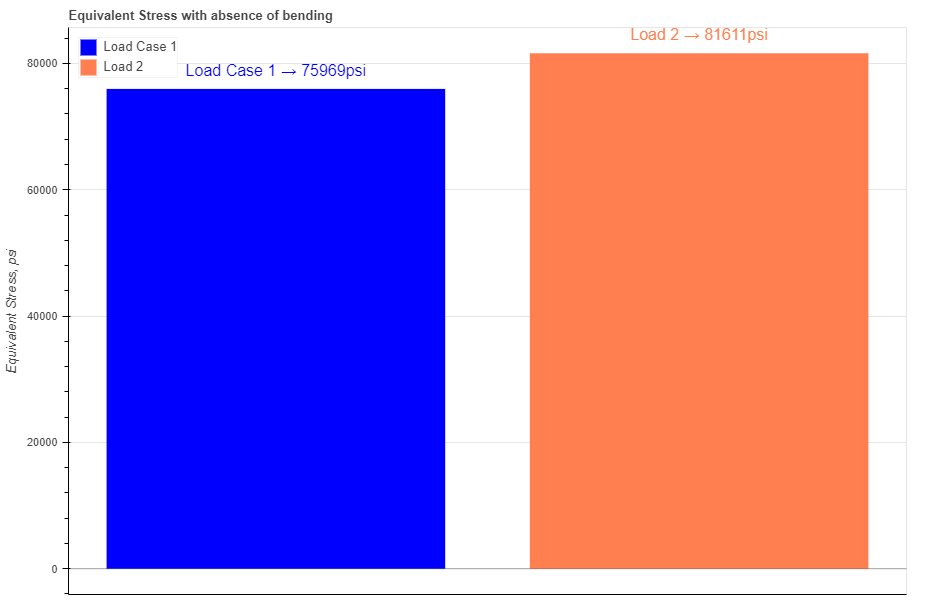

When you navigate to the "ES Equation - No Bending" page, you will come across two buttons: and These buttons allow you to include up to 5 distinct pipe specifications and up to 20 different load cases. By incorporating multiple pipes and load cases into the plot, you can conveniently compare them to one another, enabling the observation of boundaries and safe regions. An example illustrating this can be seen in Figure 22.

Figure 22: Two equivalent stresses are presented as graphical bars based on the magnitudes entered in load cases.

Hovering your cursor over any of these bars reveals headers specific to each load case. The description labeled "Location" at the lowest point indicates whether the maximum stress occurs on the outer or inner diameter of the pipe.

In the pipe section you have 2 required parameters: Outside Diameter (OD) and Inside Diameter (ID)

There are 2 more optional parameters you may input on the tubing section: minimum Wall Thickness (mWT) and Corrosion Allowance (CA). Units for mWT is % and it is based on the specified manufacturing tolerance. Common number which is used for tubing and casing in the oil industry is 87,5%. Units for CA are either in or mm, depending which system you choose by pressing buttons Corrosion allowance is a measurement to the thickness of the wall. It is a metal loss throughout the lifespan of certain material in a certain conditions.

When you fill in all parameters for the pipe, press button. It is also a good practice to give a specific name for the pipe, for example: Tubing 7"-46#. This name will be shown on the generated report and on the selection menu in the load section.

Now you can specify the loading parameters for the pipe if you press button. Here you have an option to enter internal pressure (IP), external pressure (EP), axial force (Force), torque around the longitudinal axis (Torque) and select the pipe you want to apply the loads for. If any of the magnitudes should not be specified then type 0.

Force can assume positive or negative values depending on whether it signifies tension or compression.

After you enter the required data for your analysis you can generate the report by pressing button. There you can fill the Project Name, Document Number, Created by and your Company Logo. You can also leave those fields blank and our company logo will be set on the report. To download the report you need to press button again. At the bottom of the export pop-up window you will find two html links. The first link is to download the report in PDF format and the other link is to download HTML plot, that might be useful to observe if you have high density data.

Below you may watch a short video tutorial of how to use the forms of this particular calculation.

Video: 12 ES Equation - No Bending